Azad Engineering IPO’d in 2024 and had tripled from its listing price, now in this current correction it has come to 2x of its listing price. It has marquee clients like Rolls Royce and renowned investor like Sachin Tendulkar. When a company falls in precision engineering segment, generally very difficult words are thrown to sound exotic and complex. Even Azad’s management is to be blamed for sometimes using very complicated language to hype up what they do. Azad is also thought to be in the Defense sector whereas its current major revenue comes from Energy sector. It is currently also over valued based on Price to Sales and EV to EBITDA; however I am studying this company because it is doing massive capacity expansion, 10x of what it currently has.

Azad Engineering is a name you might not hear every day, but its work powers homes, keeps planes in the sky, and supports cutting-edge defense systems. Based in Hyderabad, India, this company specializes in making high-precision components—tiny, complex parts that are absolutely critical for big machines like turbines and aircraft engines. Founded in 1983, Azad has grown from a small player into a trusted supplier for global giants like Rolls-Royce, Mitsubishi Heavy Industries, and General Electric. Their work might sound complicated because it involves advanced engineering, but in this blog, we’ll break it down into simple terms. We’ll explore what Azad does for the Energy, Aerospace and Defense sectors, and highlight their recent achievements—like massive order wins and a bold capacity expansion.

What Does Azad Engineering Do?

Let’s start with the basics. Azad Engineering makes super-precise parts for machines that do heavy lifting—think turbines in power plants or engines in airplanes. These aren’t just any parts; they’re the kind that need to be perfect because even a tiny mistake could cause a turbine to fail or a plane to malfunction. Imagine them as the “gears in a watch”—small, intricate pieces that keep everything ticking smoothly.

Here’s what they focus on:

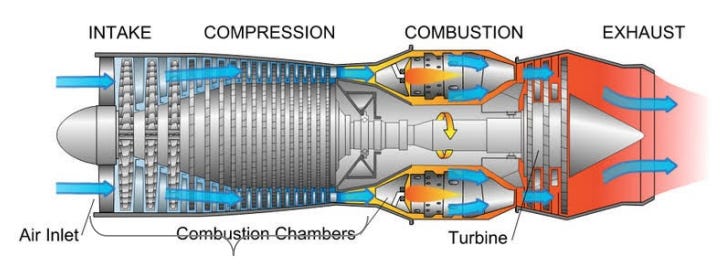

Turbines: These are machines that turn energy (like gas, steam, or nuclear power) into electricity or mechanical force. Azad makes parts like blades and airfoils—think of them as the spinning “fan blades” inside a turbine that make it work.

Aircraft Engines: Azad crafts components that go into the engines powering planes, ensuring they run efficiently and safely.

Their job is all about precision. They use advanced tools and techniques to create parts that meet incredibly strict standards—sometimes with “zero parts per million” defects, meaning no errors allowed. This level of accuracy is why companies around the world trust them with their most important machines.

Azad Engineering in the Energy Sector

Let’s dive into what Azad does for the energy sector. Picture a power plant—those massive facilities that generate electricity for your home, school, or office. Inside these plants are turbines, and Azad makes the critical parts that keep them spinning.

What They Make

Azad produces components for gas, nuclear, and thermal turbines. These include:

3D Rotating Airfoils: These are curved, wing-like pieces that help the turbine spin efficiently. They’re tricky to make because they need to be perfectly shaped to handle high speeds and heat.

Blades: The “fan blades” inside the turbine that catch the energy from gas or steam and turn it into motion.

These parts are built to survive extreme conditions—think blazing temperatures and intense pressure—while staying perfectly balanced. It’s a bit like crafting a high-performance race car engine, but for power plants.

Why It Matters

Without these precision parts, turbines wouldn’t work properly. A poorly made blade could slow down the turbine, waste fuel, or even break, causing blackouts or safety hazards. Azad’s components ensure that power plants run smoothly, delivering electricity reliably to millions of people.

Real-World Impact

Azad supplies these parts to some of the biggest names in energy, like General Electric, Siemens Energy, and Mitsubishi Heavy Industries. Recently, they signed a ₹700 crore contract with Mitsubishi to supply airfoils for advanced gas and thermal turbines. This deal shows how vital Azad is to keeping the world’s energy flowing—and how much trust global companies place in their work.

Azad Engineering in the Aerospace and Defense Sector

Now, let’s switch gears to aerospace and defense. If you’ve ever flown on a plane or admired a fighter jet, Azad Engineering’s work might have been part of it. They make parts for aircraft engines and defense systems, partnering with industry leaders like Rolls-Royce.

Azad's partners in the aerospace and defense sector include industry leaders like Boeing, Airbus, Rolls-Royce, GE Aerospace, Honeywell, and Lockheed Martin. Notably, Azad has secured a long-term contract with Rolls-Royce to supply components for both civil and defense aircraft engines. This signifies their growing importance in the global aerospace supply chain. Furthermore, Azad has been selected as the sole industry partner by the DRDO's Gas Turbine Research Establishment (GTRE) for the development and production of Advanced Turbo Gas Generator (ATGG) engines.

What They Make

Azad specializes in super critical complex machined parts—a fancy way of saying “really important, really hard-to-make components.” These include:

Engine Parts: Pieces that go into the heart of an aircraft engine, helping it generate the power to lift off and fly.

Defense Components: Parts for military aircraft and even missile systems, where reliability is non-negotiable.

Making these parts is like sculpting a tiny masterpiece. They have to be lightweight, strong, and flawless, because there’s no room for error when you’re 30,000 feet in the air or defending a nation.

Why It Matters

Aircraft engines and defense systems demand perfection. A single faulty part could lead to a plane grounding or a mission failing. Azad’s components ensure that engines perform at their best—whether it’s a commercial flight carrying passengers or a military jet protecting borders. Their work keeps planes flying and soldiers safe.

Recent Wins with Rolls-Royce

Azad has been racking up big contracts in this sector:

Civil Aircraft Engines: They signed a long-term deal with Rolls-Royce to supply critical parts for engines used in passenger planes. These parts help planes fly farther and use less fuel.

Defense Aircraft Engines: In another 7-year contract, Azad is providing components for Rolls-Royce engines in military aircraft. This is a huge vote of confidence in their ability to handle high-stakes defense projects.

Beyond Rolls-Royce, Azad also works on making critical parts for defense missiles for the international market, showing their versatility in this high-pressure field. These wins highlight how they’re becoming a go-to supplier for aerospace giants worldwide.

Pioneering Nuclear Reactor Parts

One of Azad Engineering’s proudest achievements is in the nuclear energy space. They’ve become the first Indian company approved to supply critical rotating parts for nuclear turbines—a massive milestone.

What They Make

These are specialized parts that go into turbines powered by nuclear energy. They’re assembled on turbines made in France, which then generate electricity using the heat from nuclear reactions.

Why It Matters

Nuclear energy is tricky—it’s powerful but requires top-notch safety and precision. The parts Azad makes have to meet some of the toughest standards in the world, because a failure in a nuclear turbine could be catastrophic. By breaking into this field, Azad isn’t just proving its technical skill; it’s putting India on the map as a player in the global nuclear supply chain.

A Game-Changer

This approval opens doors for Azad to work with more nuclear energy companies. It’s a testament to their ability to tackle the most complex engineering challenges—and a sign of bigger things to come.

Massive Capacity Expansion: Betting on the Future

Azad Engineering isn’t just resting on its laurels—they’re planning for explosive growth. Their recent capacity expansion is a bold move that shows they’re confident about the demand for their products.

The Plan

Azad is set to increase its manufacturing capacity by 10 times. Here’s the breakdown:

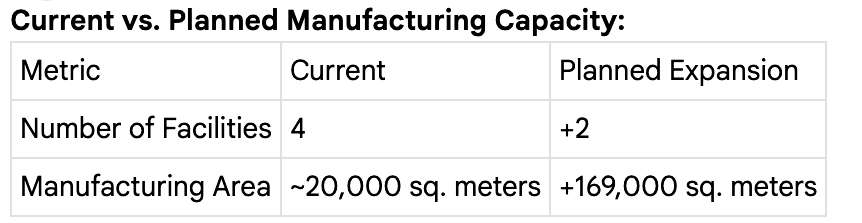

Current Setup: They already have four high-tech facilities in Hyderabad, covering 20,000 square meters.

New Facilities: They’re building two more plants in Telangana, adding over 169,000 square meters of manufacturing space. That’s like going from a small workshop to a giant factory complex!

These new plants are expected to start production in FY26 (April 2025–March 2026). This expansion will help Azad handle their growing order book, which is now worth around ₹4,500 crore—a massive jump from where they started.

Why It’s Happening

Azad’s recent order wins—like the Mitsubishi and Rolls-Royce contracts—mean they need more space and machines to keep up. Their current facilities can’t handle the workload, so they’re scaling up big time. Analysts at ICICI Securities point out that even with this growth, Azad will only capture a tiny slice of the global market—leaving plenty of room to grow further.

What It Means

This isn’t just about making more parts; it’s a signal that Azad sees a bright future. They’re betting that demand for precision components in energy and aerospace will keep rising, and they want to be ready to meet it. It’s a risky move, but with their track record, it looks like a smart one.

Demystifying Azad Engineering: The Big Picture

So, why should you care about Azad Engineering? Here's the bottom line:

They are making India a global manufacturing hub for critical technologies. By producing high-precision components within the country, Azad contributes to the "Atma-Nirbhar Bharat" (self-reliant India) initiative

They are competing with the best in the world. Azad's ability to meet the stringent quality and technical requirements of global giants in the US, Europe, China, and Japan demonstrates India's engineering prowess

They are essential to vital industries. The components Azad manufactures are crucial for the smooth and safe operation of power plants, aircraft, and defense systems, directly impacting our daily lives and national security

They are poised for significant growth. With a strong order book and a massive capacity expansion plan, Azad is well-positioned to capitalize on the growing global demand for precision engineering

They represent the spirit of Indian entrepreneurship and innovation. Starting from a single machine, Azad's journey showcases the potential of Indian manufacturing to achieve global excellence

In conclusion, while Azad Engineering might operate behind the scenes, their contribution to the energy, aerospace, and defense sectors is undeniable. By focusing on uncompromising precision and quality, they are not only powering industries worldwide but also putting India firmly on the map as a leader in critical technology manufacturing. Their recent wins, ambitious expansion plans, and the backing of prominent investors all point towards a bright future for this Indian engineering marvel.

So how does it matter? Many celebrities endorse products/companies...but how would that input really help to an investor?

I wonder since when Sachin Tendulkar became a renowned investor from a cricketer?